1) Cukurova University, Faculty of Agriculture, Dept. of Food Engineering, Balcali, Adana, 01330 Turkey; 2) Alanya Alaaddin Keykubat University, Rafet Kayıs¸ Engineering Faculty, Dept. of Food Engineering. Alanya, Antalya, 07425 Turkey; 3) Gaziosmanpaşa İlçe Tarım ve Orman Müdürlüğü, İstanbul, Turkey

Microbial quality of a confection (Tahini Halva) manufactured in Turkey

Mikrobiologische Beschaffenheit von einer in der Türkei hergestellten Süßigkeit (Tahini Halva)

Işıl Var1), Sinan Uzunlu2), Funda Gök Maviş3)

Summary

In this study, the microbiological qualities of a sweet product, tahini halva (helva, halawi), which is consumed as a ready-to-eat confection but no heat treated during production were determined for the risk assessment of public health. Between the years of 2010 to 2015, 68 halva containing pistachio, 68 halva containing cocoa and 68 plain halva samples from five tahini production companies and five different brands were analysed in Adana of Turkey. Microbiological quality of samples, in terms of total aerobic mesophilic bacteria count, yeast and mould count, Staphylococcus (S.) aureus count, coliform bacteria and Escherichia (E.) coli count, as well as the presence of Salmonella spp. were evaluated.

As a result, Salmonella spp. was found in two out of the 204 samples only in cocoa containing 68 halva samples. S. aureus was determined in three out of the 68 plain halva samples and four out of the 68 pistachio samples. Besides, the data revealed that E. coli were found in 17 % of plain halva, 26 % of halva containing cocoa and 55 % of halva containing pistachio samples.

In the present study Enterobacteriaceae species other than Salmonella spp. were identified. For instance, Citrobacter youngae, Enterobacter amnigenus, Enterobacter cloacae, Leclercia adecarboxylate, Citrobacter freundii were determined in tahini halva samples (minimum four, and maximum 13 out of 204 samples). These findings assume that food handlers practice insufficient hygienic conditions, and manufacturing is open to cross contaminations. Furthermore, based on these data it might be concluded that halva may pose health risks to consumers because of the insufficient hygienic conditions.

Keywords: Food safety, Halva manufacturing plants, Hygiene, Pathogens, Tahini halva

Introduction

Tahini halva is consumed for breakfast or dinner as a traditional confectionery in the Middle Eastern and Mediterranean countries. The manufacturing of tahini halva is simply mixing by tahini (sesame seeds paste) with sugar, citric or tartaric acid and Saponaria officinalis root extract. Nuts (pistachio, hazelnut, walnut), cocoa and flavours are added to produce for variety (Osaili et al., 2017). Detailed manufacturing process is available in Var et al. (2007).

Even a roasting treatment is applied at 110 to 150 °C for 30 to 60 min, which is considered to inactivate the microorganisms in the tahini process, the risk of common foodborne pathogens is still present owing to the contaminated ingredients (tahini and nuts) and improper hygienic conditions of halva manufacturing plants and food-handlers (Osaili et al., 2016a; Osaili et al., 2017). Using additives with low microbial quality in halva manufacturing (e. g. cocoa powder and pistachio) decreases the quality of the produce. Even aflatoxin formation majorly sourced by pistachio was reported formerly in tahini halva (Var et al., 2007). Because of the tahini halva process consists no thermal process the product raises major food safety concerns.

Tahini halva is assumed in general a safe product and displayed for one year at room temperature in retail. Tahini halva has a low water activity (aw) level (0.17 to 0.23), and moisture content (below 3 %) (Osaili et al., 2017). However, many outbreaks were reported owing to the consumption of tahini and tahini halva in imported countries, such as Germany, Sweden, Norway, Australia, New Zealand, and the United States in the last two decades (Osaili et al., 2017).

Turkey is the leading producer of tahini halva, and exports to several countries. Therefore, the aim of this study was to monitor the microbiological quality of tahini halva, sampled from halva manufacturing plants and supermarkets in Adana, a province of Turkey during the years 2010 to 2015.

Material and Methods

Materials

A total of 204 tahini halva samples within their original packages comprised from 68 plain halva, 68 halva containing cocoa, and 68 halva containing pistachio, were randomly purchased from five different brands of halva which are sold at supermarkets and five different halva manufacturing plants. Samples were collected at regular intervals between the years of 2010–2015 and were stored at 2–8 ˚C until further analysis.

Microbiological analysis

To determine the microbiological quality of tahini halva samples, 10 g of each sample was handled under the routine aseptic conditions. Samples were homogenized with 90 ml sterilized dilution water (peptone water, 0.1 %) for serial dilutions. Total viable counts of aerobic mesophilic bacteria (TVC) and yeast-mould (YM) were enumerated at Nutrient Agar (Merck, Germany) and Potato Dextrose Agar (Merck, Germany), respectively. Petri dishes were incubated at 30 ˚C for 48 h and 25 ˚C for 3–5 days for TVC and YM, respectively (Beuchat et al., 1991; Osaili and Al-Nabulsi, 2016b). Baird Parker Agar (Merck, Germany) supplemented with Egg Yolk Tellurite solution (Merck, Germany) was used for enumeration of S. aureus, and incubated at 37 °C for 24 h according to ISO 6888. Suspected S. aureus colonies were transferred into tubes containing 0.2–0.3 ml Brain Heart Infusion (BHI) broth (Merck, Germany) for confirmation. Grown cultures were subsequently incubated for 18–24 h at 35 °C. Bactident Coagulase (Merck, Germany) was added to the BHI culture, and incubated at 35 °C and examined periodically over 6 h period for clot formation (Anonymous, 2005).

Enumeration of coliform bacteria and E. coli were evaluated by performing Most Probable Number (MPN) technique and Fluorocult Lauryl Sulfate Broth (Merck, Germany) was used. One millilitre of the dilutions was transferred to three tubes and incubated at 37 ˚C for 24 h. Presumptive positive (gassing) tubes were observed and detected as coliform group bacteria. For enumerating E. coli, tubes were exposed to a long wave (366 nm) UV light in a darkened area and tubes reflecting fluorescence were examined for IMVIC patterns (AOAC 2002).

Salmonella spp. analyses in tahini halva samples were carried out according to a combination of ISO 6579 and FDA procedures. An aliquot of 25 g sample was used for pre-enrichment of tahini halva samples in 225 ml of Buffered Peptone Water (Merck, Germany) and the broth cultures were incubated. After incubation at 37 ˚C for 16–20 h, one millilitre was transferred to 10 millilitres of selective enrichment broth of Selenite Cystein Broth (Merck, Germany) and 0.1 ml to 10 ml Rappaport Vassiliadis Broth (Merck, Germany). Incubation periods were 24 h at 35 °C for each tubes. A loop from the both enrichment broths were then streaked onto Hectoen Enteric Agar (Merck, Germany) and Xylose Lysine Deoxycholate Agar (Merck, Germany) plates. These plates were incubated for 20–24 h at 35 °C and checked for typical colonies. Five presumptive colonies were confirmed by Lysine Iron Agar (Merck, Germany) and Triple Sugar Iron Agar (Merck, Germany) slants by incubating at 35 °C for 24 h. Each presumed-positive cultures from TSI slants were transferred into Urea broth tubes with a sterile needle, and incubated for 24 h at 35 °C. All typical cultures were further identified by using API 20 E (Analytical Profile Index, Biomérieux) and serological polyvalent flagellar and somatic tests (Forsythe and Hayes, 2000; Anonymous 2002).

Data handling and analysis

The data were analysed using SPSS version 20 software. Prior to data analysis, normality and equality of variances were tested using the Shapiro-Wilk and Levene tests. In those cases, where Levene’s test was significant, log transformation was used. The values obtained for CFU (colony forming unit)/g of samples were transformed into log10 (x+1) values. However, in those cases when transformations failed to meet the requirements for parametric analyses, the non-parametric Kruskal-Wallis test was used, and mean values were subsequently separated by the Mann-Whitney U-test.

Results and Discussion

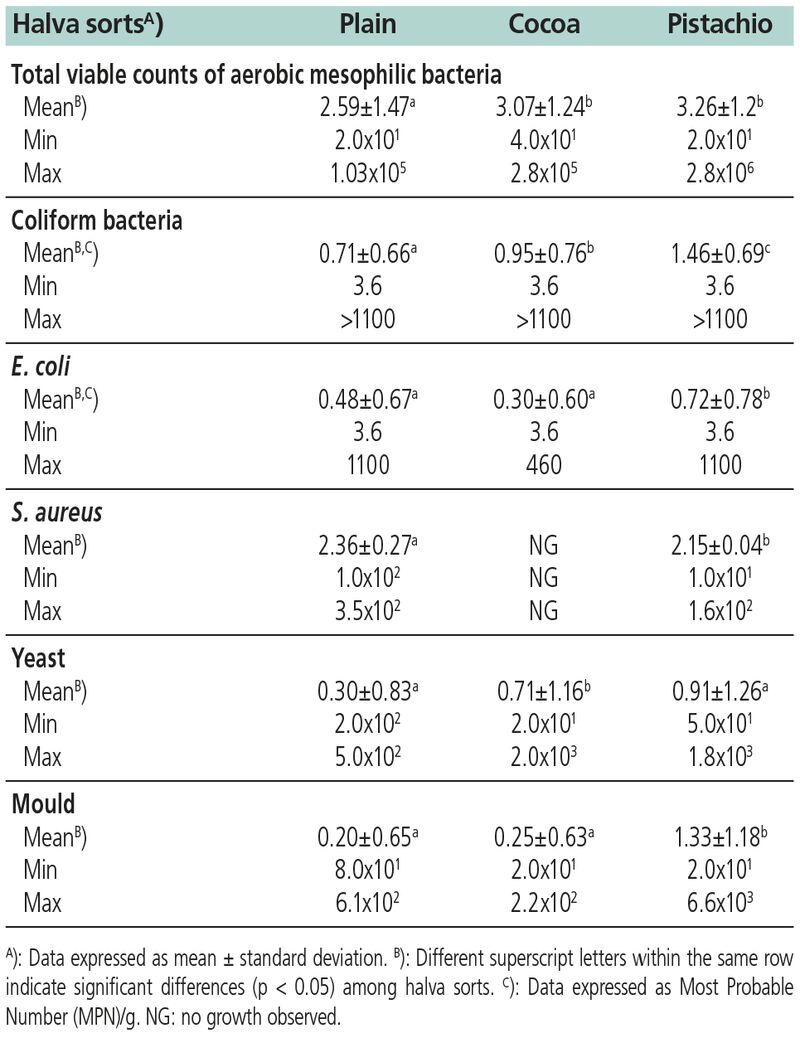

The results of microbiological analyses of tahini halva samples (N=204) were presented in Table 1.

Total viable counts of aerobic mesophilic bacteria (TVC) were counted in 82 % of plain halva samples, 94 % of halva containing cocoa and 97 % of halva containing pistachio. The mean values of halva containing cocoa and pistachio were found higher than the plain halva samples (Table 1). This is probably resulted from the cocoa and pistachio usage in halva manufacturing. However, poor personal hygiene also determines the final product quality, as stated earlier (Kahraman et al., 2010).

Osaili et al. (2017) reported that TVC of halva samples was 2 log CFU/g. This was similar with our mean data for TVC of plain halva samples (Table 1). Kahraman et al. (2010) found higher results. The mean of the 120 samples in Marmara region of Turkey was 4.63 log CFU/g for TVC. Sengun et al. (2005) reported that the mean TVC data were in the range of 2 to 4 logs in different halva types, retailed in İzmir, Turkey. They reported that mean data of plain halva for TVC was 3.91 CFU/g.

TVC is one of the frequently used indicator of hygienic conditions when assessing food quality. Having high TVC value in the same time reflects the probable presence of pathogenic bacterial types in foods (Kahraman et al., 2010). S. aureus is one of those pathogenic bacteria, however is highly vulnerable to heat treatment and almost many sanitizing agents. Therefore, the well-known fact that presence of this bacterium or its enterotoxins in processed foods or in food processing equipment is accepted as an indication of poor hygienic and sanitation conditions. In this study, S. aureus counts were found in 3 % of plain halva samples and 5 % of halva samples containing pistachio, while no growth was observed in halva samples containing cocoa.

Yiğit et al. (2006) reported that S. aureus counts were ranged from 30 to 100 CFU/g in 20 tahini halva samples in Bursa, a province of Turkey. Contamination of S. aureus as reported might be aroused from food handler’s skin, mouth and nose. Kahraman et al. (2010) also reported a low value (1.47 CFU/g) for S. aureus in halva samples, which were marketed in Marmara region of Turkey. In our case we reported higher data than those, therefore the mean was 2.54 CFU/g.

Our research group have already reported aflatoxin presence in nuts (Var et al., 2018), sesame products, and in tahini halva (Var et al., 2007). Hence, Kotzekidou (1998) have reported no mould growth in tahini halva. Moulds are widely presence in environment either in air, water, soil and dust. These microorganisms may pose potential threats to the human health by mycotoxin production and cause allergic reactions (Mashak et al., 2014). Moulds were counted in 8 % of plain halva samples, 14 % of halva samples containing cocoa and 61 % of halva samples containing pistachio. Moulds reduce the quality of foods and may pose health problems in consumers (Kahraman et al., 2010).

Sengun et al. (2005) indicated that halva containing pistachio had the highest count (2.53 CFU/g) for moulds among the other kinds of halva. Similarly, we found that the mean values for mould were highest among halva samples that contain pistachio (Table 1). Contamination of tahini halva samples with moulds and yeasts could be resulted majorly from raw nuts, and subsidiary from packaging materials. Containing high rate sugar (> 80 Brix) confectionery, such as tahini halva, do favours the growth of xerotolerant yeast and mould species. For instance, yeasts were counted in 11 % of plain halva samples, 29 % of halva samples containing cocoa and 35 % of halva samples containing pistachio. The obtained mean data for yeast were lower than 1 log CFU/g in halva samples (Table 1). Hence, Kotzekidou (1998) reported yeast counts in tahini halva samples in the range of 4x101 to 4.9x103 CFU/g. However, Ayaz et al. (1986) and Sengun et al. (2005) determined the yeast counts as much as lower (< 10 to 50 colonies per gram).

Detection of coliforms is used as a general indicator of sanitary conditions in the food processing environments. Therefore, the presence of coliform bacteria is routinely checked to determine the microbiological safety of raw or processed foods by regulatory agencies world-wide (Molina et al., 2015). In this study, coliform bacteria were found in 67 % of plain halva samples, 76 % of halva samples containing cocoa and 97 % of halva samples containing pistachio. The most ubiquitous type of coliform group is E. coli. The data revealed that E. coli were found in 17 % of plain halva samples, 26 % of halva samples containing cocoa and 55 % of halva samples containing pistachio.

The results clearly showed that E. coli in halva containing pistachio were more contaminated than the other halva kinds (Table 1). Turkish Food Codex limits the growth of E. coli to be lower than 1 log CFU/g in retailed halva sorts (Turkish Food Codex 2011). Some of our samples (one plain, two cocoa, five pistachio halva sorts) were higher than the specified, while most of the samples were lower than the limit value (lower than 1 log CFU/g). Our results seem to be in accordance with previous studies of Ayaz et al. (1986), Kotzekidou (1998), and Sengun et al. (2005). The sources of microbial contamination may be the poor personal hygiene and environment during the post-harvesting stage of pistachio nut. Members of Enterobacteriaceae (e. g. Salmonella, E. coli) are the most reported food poisoning cases throughout the world, such as salmonellosis and traveller’s diseases. The infectious dose of Enterobacteriaceae are varied. For instance, some Shigella spp. reported to be as low as than 10 organisms, while different serovars of Salmonella and strains of E. coli was reported higher than 5 logs (Kothary and Babu, 2001). E. coli is abundant in human and animal faeces and not usually found in other niches. E. coli, is a potential pathogenic bacterium and an important faecal indicator in foods (Mashak et al., 2014). The optimum conditions for its growth will also favour the growth of Salmonella. In this study, Salmonella spp. were detected in two (cocoa type) out of 204 halva sorts samples. According to, El-Sherbeeny et al. (1985) from Egypt, Sengun et al. (2005) from Turkey and Kotzekidou (1998) from Greece reported no presence of Salmonella spp. in tahini halva samples. However, the fact that Salmonella spp. is able to grow in foods with low aw values (Hockin et al. 1989). Furthermore, the survival in dry environmental conditions is characteristic for this organism. For instance, the cells of this organisms can survive in bitter chocolate for months, which has a low (0.3 to 0.5) aw value (King et al., 2011). Exposure to one stress might result in cross-resistance of the microbe to heterogeneous stresses, and the survival of microbes is enhanced (Osaili et al., 2017).

Besides, the bacterium may grow in cocoa beans and powder, which were used in halva manufacturing. In a report, Salmonella serotypes were inactivated at 120 °C for 30 mins and 110 °C for 40 mins, when inoculated at level of 6 log CFU/g in cocoa beans (Nascimento et al., 2012). Additionally, Torlak et al. (2013) showed that roasting process conditions (110 to 150 °C for an hour) of sesame seeds when used in tahini manufacturing is sufficient to inactivate 5 logs of Salmonella cells, but cross-contamination (e. g. personnel) should be prevented after roasting. As Salmonella cells have been found to survive at least 16 weeks at 4 and 22 °C storage periods.

In the present study, Enterobacteriaceae species other than Salmonella spp. were identified. For instance, Citrobacter youngae, Enterobacter amnigenus, Enterobacter cloacae, Leclercia adecarboxylate and Citrobacter freundii were detected in tahini halva samples (minimum four, maximum 13 out of 204 samples). These findings clearly showed that in accordance with the earlier studies (Kotzekidou 1998; Brockmann et al., 2004), food handlers practice insufficient hygienic conditions and manufacturing is open to cross contaminations.

The composition of halva is characteristically high in sugars (47.7 % w/w), fat (32.4 % w/w), and proteins (13.7 % w/w), but low in dietary fibres (1.5 % w/w) (Elleuch et al., 2014). Content of fat supports the growth of E. coli and Staphylococci in tahini halva, which could transform the product into a potential public health hazard (Kotzekidou 1998; Mashak et al., 2014). For instance, Kotzekidou (1998) pointed out that Salmonella Enteritidis have survived in halva in post-processing for at least eight months of storage at 6 and 18–20 °C. Osaili et al. (2017) have reported that they found Salmonella spp. survived in tahini having different levels of aw (0.17, 0.35 and 0.50) value at 10 and 25 °C storage for twelve months of storage. Researchers have stated that colloidal texture (suspension of lipid and water) of halva gives opportunity to Salmonella cells for survive. This was also valid for peanut butter, reported by Osaili et al. (2017) that survival rate of Salmonella spp. cells was affected by the size of lipid and water droplets which dispersed in peanut butter.

Sesame seeds are rich in phytochemicals, and have phenolic compounds to exert antimicrobial effect. The findings of earlier documents have underlined that Salmonella spp. survived better at low storage temperature degrees compared with high storage temperature degrees (Kotzekidou, 1998; Osaili et al., 2017). The reason was explained as the ratio of unsaturated fatty acids to saturated fatty acids in cell membrane is higher at 25 °C than at 10 °C. This affects the permeation capacity of cell membrane, such as for phenolic compounds, to enter the cell and express the antimicrobial effect. Because sesame seeds are rich in lignans, and trace amounts of sesamol, which were reported that have antimicrobial effect against Bacillus cereus, S. aureus and Pseudomonas aeruginosa (Osaili et al., 2017).

In addition, having heat and cold shock proteins protect Salmonella cells against the temperature effect. Osaili et al. (2017), have studied the heat (at 50 °C) and desiccation stressed Salmonella spp. in halva at 10 and 25 °C storage for twelve months. The results revealed that halva having low aw value (0.19), high fat content (32.7±3.6 %) and presence of phenolic compounds (10.6±1.0 mg/g) did not prevent the survival of Salmonella spp. in halva in the storage period. Inoculated (6–7 logs) cells were decreased by 5.2 to 6.3 log CFU/g at 25 °C, while this was 2.6 to 2.8 log CFU/g at 10 °C storage for different samples (control, desiccated or heat stressed).

Craven et al. (1975) have isolated Salmonella Eastborne from chocolate and reported that its source might be cocoa powder in an international outbreak, between 1973 and 1974 in 80 cases. The presence of two isolates of Salmonella spp. cells in halva containing cocoa samples in our findings might be attributed to cocoa powder.

Little (2001) reported that 90 samples of imported halva from Turkey and Lebanon into the UK market contained no Salmonella spp. positive. However, the year 2001 was recorded as the halva sourced international outbreaks caused by S. Typhimurium DT 104 in Austria and other European countries (Khaschabi et al., 2005). For instance, in Sweden 27 people predominantly having Arabic names have been infected by S. Typhimurium DT 104 after consuming halva. The age of the cases was ranged from five months to 50 years, but 15 of the cases were being younger than ten years old, and no dead was occurred. Imported halva jars in 350 g and 750 g boxes were also confirmed that jars contain S. Typhimurium DT 104. Five jars of halva, four with pistachio and one with cocoa flavouring were the positive samples. In Germany during the years 2000 and 2001 the occurred cases caused by laboratory isolates of S. Typhimurium were strongly associated with the Turkish or Arabic names. S. Typhimurium R type ASSut was isolated from a sesame paste manufactured by the same producer. The importance of the strain S. Typhimurium DT 104 is its multi resistance to ampicillin, chloramphenicol, streptomycin, sulfonamides, and tetracyclines (ACSSuT) (Brockmann, 2001). Fisher et al. (2001) have reported that halva imported from Turkey in two brands containing chocolate, plain and pistachio flavours have been contaminated by S. Typhimurium DT 104 in Australia. The strains were found resistant to ACSSuT and spectinomycin. In Melbourne’s Turkish community 23 persons have been affected by S. Typhimurium DT 104 infection. Australian food safety agencies were able to recover about 87 percentages of imported halva samples in the country (Kaldor et al., 2002). In Minnesota (the USA) two infants were affected by salmonellosis after consuming a brand of tahini sesame paste, in 2013 (Walsh 2013). Extensively, CDC (Centers for Disease Control) and FDA (Food and Drug Administration) in the USA have investigated multistate outbreak of Salmonella infections. Very rarely seen strains of S. Montevideo and S. Mbandaka have infected sixteen persons in nine states. Four interviewed ill persons have told that they consumed homemade hummus made with the same brand of tahini sesame paste in the week of illness (CDC 2013). FDA reports the problematic imported foods on its website. Tahini is called as sesame paste and halva is called as sweet sesame paste on the FDA website. Salmonella associated halva was reported from Egypt in 2009 and in 2012 from Turkey, where tahini was imported from Egypt, Lebanon and Syrian Arab Republic in 2009 (FDA 2019). More recently on 27 February 2019, eight persons were infected with Salmonella Concord in four states in the USA. The imported tahini products from Israel was the source of illnesses (CDC 2019).

TABLE 1:

Microbial contaminants of halva samples log Colony Forming Unit (CFU)/g.

Conclusions

As a conclusion, halva samples in the present study were found to have been found to be contaminated with microorganisms. Microbial quality of the main raw material (tahini) of halva and personal hygiene directly determines the quality of the halva production. No thermal process is applied in the tahini halva manufacturing to destroy microorganisms. Therefore, food safety management systems of manufacturers should be strictly monitored by the authorities to protect the public health. Furthermore, we propose to add Salmonella parameter into the Turkish Food Codex for halva.

Conflict of Interest

The authors declare that for this article they have no actual, potential or perceived the conflict of interests.

References

Anonymous (2002): Api® 20 E Identification system for Enterobacteriaceae and other non-fastidious Gram-negative rods. Ref 20 100 / 20 160. Retrieved on July 18, 2019 from: http://biomanufacturing.org/uploads/files/587872707301898351-api20einstructions.pdf

Anonymous (2005): Merck Gıda Mikrobiyolojisi Uygulamaları. Halkman, A. K. (bas¸ ed.), Bas¸ar Matbaacılık Ltd. Şti., Ankara, 358 s. ISBN: 975-00373-0-8.

AOAC (2002): Official Methods of Analysis, 17th ed., Bacteriological Analytical Manual. Chapter 4: Enumeration of Escherichia coli and the Coliform Bacteria. Feng, P. Weagant, S. D. Grant, M. A. and W. Burkhardt. Retrieved on July 18, 2019 from: https://www.fda.gov/food/laboratory-methods-food/bam- 4-enumeration-escherichia-coli-and-coliform-bacteria.

Ayaz M, Sawaya WN, Al-Sogar A (1986): Microbiological quality of tehineh manufactured in Saudi Arabia. J. Food Protect. 49, 504–506.

Beuchat LR, Nail BV, Brackett RE, Fox TL (1991): Comparison of the PetrifilmTM yeast and mold culture film method to conventional methods for enumerating yeasts and molds in foods. J. Food Protect. 54, 443–447.

Brockmann SO, Piechotowski I, Kimming P (2004): Salmonella in sesame seed products. J. Food Prot. 67, 178–180.

Brockmann S (2001): International outbreak of Salmonella Typhimurium DT104 due to contaminated sesame seed products – update from Germany (Baden-Württemberg). Eurosurveillance Weekly volume 5, issue 33, 16/Aug/2001. Retrieved on July 18, 2019 from: https://www.eurosurveillance.org/content/10.2807/esw.05.33.01699-en

CDC (2013): Multistate Outbreak of Salmonella Montevideo and Salmonella Mbandaka Infections Linked to Tahini Sesame Paste (Final Update). Retrieved on July 18, 2019 from: https://www.cdc.gov/salmonella/montevideo-tahini-05-13/index.html

CDC (2019): Outbreak of Salmonella Infections Linked to Tahini from Achdut Ltd. Retrieved on July 18, 2019 from: https://www.cdc.gov/salmonella/concord-11-18/index.html

Craven PC, Baine WB, Mackel DC, Barker WH, Gangarosa EJ, Goldfield M, Rosenfeld H, Altman R, Lachapelle G, Davies JW, Swanson RC (1975): International outbreak of Salmonella Eastbourne infection traced to contaminated chocolate. The Lancet 305, 788–792.

Elleuch M, Bedigian D, Maazoun B, Besbes S, Bleckerand C, Attia H (2014): Improving halva quality with dietary fibres of sesame seed coats and date pulp, enriched with emulsifier. Food Chem. 145, 765–771.

El-Sherbeeny M, Saddik MF, Bryan FL (1985): Microbiological profiles of foods served by street vendors in Egypt. Int. J. Food Microbiol. 2, 355–364.

FDA (2019): Import Alert 99-19. Retrieved on July 18, 2019 from: https://www.accessdata.fda.gov/cms_ia/importalert_263.html

Fisher I, Andersson Y, de Jong B, O’Grady KA, Powling J (2001): S. typhimurium DT104, imported helva – Australia, Sweden. ProMED-mail post, archive number: 20010809.1884. Retrieved on July 18, 2019 from: https://www.promedmail.org/post/2200381

Forsythe SJ, Hayes PR (2000): Food hygiene, microbiology and HACCP. Springer. New York, USA.

Hockin JC, D’aoust JY, Bowering D, Jessop B, Khanna H, Liorand H, Milling ME (1989): An international outbreak of Salmonella Nima from imported chocolate. J. Food Prot. 52, 51–54.

Kahraman T, Ghassan I, Ozmen G, Buyukunal S (2010): Microbiological and chemical quality of tahini halva. Brit. Food J. 112, 608–616.

Kaldor J, Cameron AS, Harris A, Mead PS, Kennedy M (2002): OzFoodNet: report of the external review team, Canberra, Australia: Department of Health & Ageing.

Khaschabi D, Schöpf K, Berghold C (2005): Occurrence of multi-resistant Salmonella enterica Typhimurium DT 104 in Austria isolated from humans, animals and food. Int. J. Antimicrob. Ag. 25, 272–277.

King N, Lake R, Cressey P (2011): Risk profile: Salmonella (non-typhoidal) in poultry (whole and pieces). Ministry for Primary Industries, Technical Paper No: 2015/04. ISBN No: 978-0-477-10568-2 (online). Wellington, NZ.

Kothary MH, Babu US (2001): Infective dose of foodborne pathogens in volunteers: A review. J. Food Safety 21, 49–73.

Kotzekidou P (1998): Microbial stability and fate of Salmonella Enteritidis in halva, a low-moisture confection. J. Food Protect. 61, 181–185.

Little C (2001): International outbreak of Salmonella Typhimurium DT104 – update from the United Kingdom. Eurosurveillance Weekly volume 5, issue 33, 16/Aug/2001. Retrieved on July 18, 2019 from: https://www.eurosurveillance.org/content/10.2807/esw.05.33.01700-en

Mashak Z, Sodagari H, Moradi B (2014): Microbiological and chemical quality of Sohan: An Iranian traditional confectionary product. J. Food Qual. Hazards Control 1, 56–60.

Molina F, López-Acedo E, Tabla R, Roa I, Gómez A, Rebollo JE (2015): Improved detection of Escherichia coli and coliform bacteria by multiplex PCR. BMC Biotechnol. 15, 1–9.

Nascimento MS, Brum DM, Pena PO, Berto MI, Efraim P (2012): Inactivation of Salmonella during cocoa roasting and chocolate conching. Int. J. Food Microbiol. 159, 225–229.

Osaili TM, Al-Nabulsi AA, Abubakar SA, Alaboudi AR, Al-Holy MA (2016a): Feasibility of using gamma irradiation for inactivation of starvation-, heat-, and cold-stressed Salmonella in tahini. J. Food Protect. 79, 963–969.

Osaili TM, Al-Nabulsi AA (2016b): Inactivation of stressed Escherichia coli O157:H7 in tahini (sesame seeds paste) by gamma irradiation. Food Control, 69, 221–226.

Osaili TM, Al-Nabulsi AA, Nazzal DS, Shaker RR (2017): Effect of storage temperatures and stresses on the survival of Salmonella spp. in halva. Letters Appl. Microbiol. 65, 403–409.

Sengun IY, Hancioglu O, Karapinar M (2005): Microbiological profile of helva sold at retail markets in Izmir city and the survival of Staphylococcus aureus in this product. Food Control 16, 840–844.

Torlak E, Sert D, Serin P (2013): Fate of Salmonella during sesame seeds roasting and storage of tahini. Int. J. Food Microbiol. 163, 214–217.

Turkish Food Codex (2011): Mikrobiyolojik kriterler yönetmeliği. 29 Aralık 2011 tarih ve 28157 sayılı Resmi Gazete, Ankara. Retrieved on July 18, 2019 from: http://www.resmigazete.gov.tr

Var I, Kabak B, Gök F (2007): Survey of aflatoxin B1 in halva, a traditional Turkish food, by TLC. Food Control 18, 59–62.

Var I, Sağlam S, Uçkun O, Hashmati B (2018): The Microbiological Quality Of Edible Nuts. Proceedings of the International Conference on Raw Materials to Processed Foods (RP-Foods 2018), Antalya, Turkey, 2018, 54.

Walsh P (2013): Salmonellosis – USA (07): (Minnesota) sesame seed paste, alert, recall. ProMED-mail post, archive number: 20130518.1721490. Retrieved on July 18, 2019 from: http://www.promedmail.org/post/1721490

Yiğit A, Şahan Y, İrkin R, Korukluoğlu M (2006): Bursa’da satışa sunulan tahin helvalarının kimyasal ve mikrobiyolojik özellikleri. Proceedings of the 9th Food Congress, Bolu, Turkey 2006, 260–272.

Address for Correspondence

Sinan Uzunlu

Alanya Alaaddin Keykubat University

Rafet Kayıs¸ Engineering Faculty

Dept. of Food Engineering

Alanya, Antalya, 07425

Turkey

Weitere Informationen zum Beitrag

Arch Lebensmittelhyg 71,

124–128 (2020)

DOI 10.2376/0003-925X-71-124

Copyright

© M. & H. Schaper GmbH & Co.

ISSN 0003-925X